Track machine status, operational efficiency, and production throughput with real-time dashboards.

Transforming Manufacturing with AI-Powered Insights

The power of AI-driven analytics to revolutionize industrial operations. With EdgeSync AI, LanSight AI, OmniAI Suite, and OpFact, manufacturers gain unparalleled real-time visibility, predictive intelligence, and automated decision-making capabilities. These AI-powered solutions optimize production processes, minimize downtime, and drive continuous improvement across the factory floor.

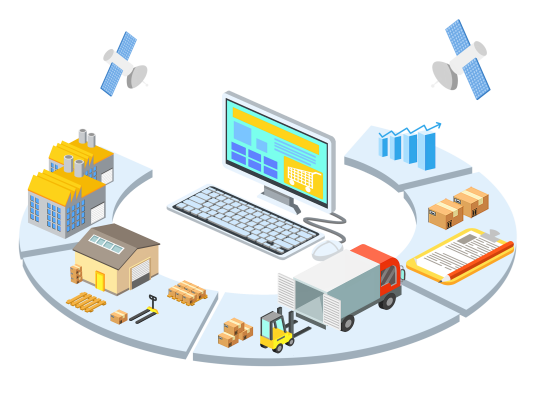

Real-Time Production Analytics

EdgeSync AI enables real-time data insights by seamlessly integrating with PLCs, IoT devices, and industrial sensors. It continuously monitors machine performance, process efficiency, and key operational metrics, ensuring complete transparency into production health.

Predictive Maintenance & AI Diagnostics

LanSight AI predicts potential equipment failures before they happen, enabling proactive maintenance planning that reduces unexpected downtime and maintenance costs. Using historical data and real-time machine learning algorithms, LanSight AI enhances diagnostics and failure prevention.

AI-Powered Demand Forecasting & Workflow Optimization

OmniAI Suite leverages AI and machine learning to accurately predict production demand and optimize workflows. By analyzing market trends, supply chain data, and real-time production insights, it ensures efficient resource allocation and lean manufacturing practices.

AI-Driven Quality Control & Defect Detection

OpFact enhances quality assurance by utilizing AI-driven defect detection and automated quality control. Through computer vision and sensor-based anomaly detection, it ensures manufacturing precision and reduces waste.

Unlocking the Power of AI for Industrial Excellence

With EdgeSync AI, LanSight AI, OmniAI Suite, and OpFact, manufacturers gain deep industrial insights, reducing downtime, optimizing workflows, and ensuring top-tier quality control.

-

Real-Time Data Analytics

Monitor and analyze industrial data with AI-powered insights.

-

Predictive Maintenance & AI Diagnostics

Predict and prevent equipment failures using AI-driven diagnostics.

-

AI-Powered Demand Forecasting

Optimize production scheduling with AI-powered forecasting.

-

Automated Quality Control

Ensure product quality with automated AI-based inspections.

Revolutionizing Manufacturing with Industrial AI Insights

By integrating EdgeSync AI, LanSight AI, OmniAI Suite, and OpFact, manufacturers can achieve unprecedented levels of automation, efficiency, and predictive intelligence. AI-powered manufacturing enables cost reduction, enhanced product quality, and seamless digital transformation, ensuring businesses stay ahead in the competitive industrial landscape.

Book Your Exclusive Demo – Let’s Get Started!